Flexible Beam-To-Beam Connections

Just about every beam-to-beam connection will fall into this category and there are a number to choose from. The engineer will rarely dictate which connection type to use, preferring instead to leave it up to the fabricator and his right-hand-man - the detailer.

To assist the detailer in analyzing the pro's and con's of each connection type. we've prepared a Selection Guide

The connection types listed here cover pretty much all the available options - but there will always be an odd exception, which unfortunately you may have to work out for yourself.

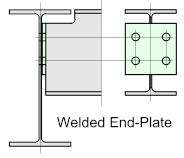

Welded End-Plates

These are welded to the beam end and site bolted to the web of the supporting beam. These are probably the most popular end connection type as they are simple and straightforward to fabricate, cost effective and lend themselves to a high degree of Standardization.

For more information on End-Plates refer to Flexible Connections > Welded End-Plates

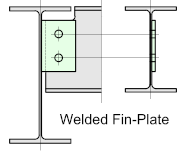

Welded Fin-Plates

The Fin-Plate is welded to the web of the supporting beam, while the incoming beam is site-bolted through the web to the mating face of the Fin-Plate. Fin-Plates come in numerous configurations, each of which are straightforward to fabricate and easy to erect

For more information on Fin-Plates refer to Flexible Connections > Welded Fin-Plates

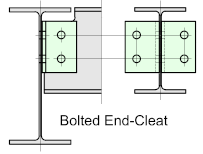

Bolted End-Cleats

Also known as Clip Angles. They are usually formed from standard hot-rolled angle sections and shop-bolted to the beam end. They are then site bolted to the web of the supporting beam. depending on how they are configured they lend themselves to a high degree of Standardization

For more information on End-Cleats refer to Flexible Connections > Bolted End-Cleats

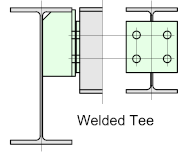

Welded Tees

The Tee is shop-welded to the web and inside flange of the supporting beam – the Flange of the Tee is then shop-welded to the end of the web-plate and the flange of the beam. The incoming beam is fitted with and End-Plate or Cleat, which is then site-bolted to the Tee.

For more information on Tee connections refer to Flexible Connections > Welded Tee-Connections

Flexible Beam-To-Column Connections

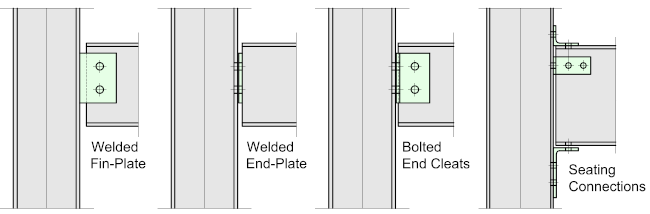

Beam to Column Flange

When connecting a beam to a column flange, the hole pitch is determined by the Standard or Workable Gauge of the column. This of course is not mandatory, but a recommendation offered by steel institutes worldwide. Most detailers follow these rules as it goes a long way in improving Standardization.

The common means of connection are similar to the beam-to-beam connections, and include:

- Welded End Plates - which are by far the most common as they not only offer the advantages of the beam-to-beam option, but lend themselves to the addition of Gusset-Plates when Vertical Bracing is to be added.

- Bolted End-Cleats are also a common option, they can be easily adapted to accommodate Gusset-Plates, but will only work with columns with a flange width exceeding 200 mm.

- Welded Fin-Plates are a good option for lightly loaded connections, but if the incoming beam is not laterally restrained close to the connection it can lead to horizontal deflection

- Seating Connections - There are a few applications for Seating Connections which include: Seating Cleats, Column Cap-Plates and Corbels, which usually apply to Crane rails.

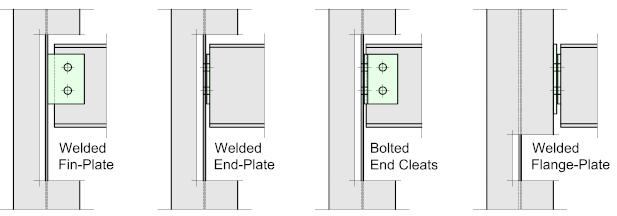

Beam to Column Web

You're probably seeing a pattern here, but connecting to the column web requires a little more thought - the bolt-hole gauge is not prescribed but is rather determined by the space available inside the flanges of the column.

In the event that the column web may be too short to accommodate the connection you can weld a Flange-Plate across the toes of the column flange and connect to that. This can be made to work for any of the other connection options

Notes on Beam to Column Connections

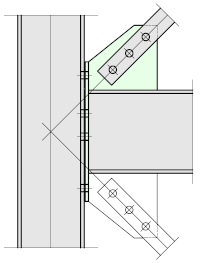

Gusset Plates

With beam-to-column connections there's a good chance that the connection must be integrated with the Vertical Bracing - in which case, provision will have to be made to accommodate Gusset-Plates.

The example to the right shows a typical Gusset-Plate attached to an End-Plate, but they can be adapted to Bolted End-Cleats.

For more information of fitting Gusset-Plates and the options available see Vertical Bracing > Gusset-Plates