Typical Examples

Bolting beam to beam using hollow sections is not widely used - it can prove to be quite costly due to the welding of the various components of the joint. Also, the joint is exposed and is not particularly aesthetically pleasing (Though there is a hidden joint option, which we'll look at later)

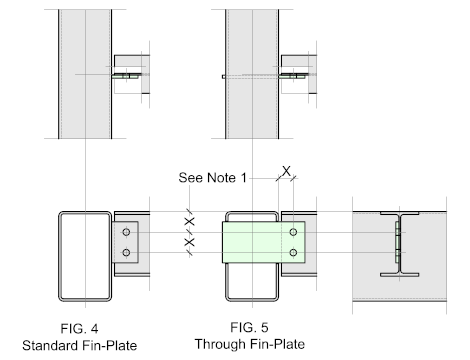

That being said, below are a few examples of such connections:

Fig. 1 illustrates a typical connection using a Tee section welded to the end of the incoming member connecting to the Fin-Plate which is welded to the outside face of the supporting beam. The Tee may be a standard hot-rolled profile, or alternatively may be fabricated from plates. The incoming beam will therefore have a closed end.

Fig. 2 shows a variation of the former using a tongue plate which is welded to the inside of the profile extending to a depth not less than the depth of the beam. For large profiles the welding of the plate will not present a problem, but for smaller sections access to the weld may prove problematic, in which case the option shown in figure 3 may be more suitable.

Normally, this will result in a open ended beam, but often closure plate are welded to the beam end and tongue plate to seal the inside of the profile.

Fig. 3 shows a further variation using an extended tongue plate. In this case the plate is not welded inside the profile but is fitted into a slot cut into the top and bottom and welded from the outside. As with Fig. 3 - closure plates may be added.

Though these are listed as beam to beam connection options, they are more commonly found as Bracing Connections, which will be included in this series of articles.

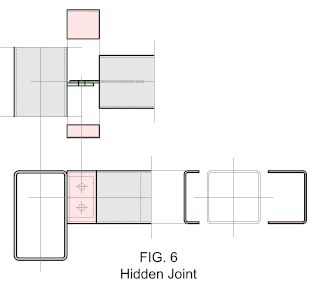

Hidden Connections

As mentioned earlier, beam to beam fin plate connections can look a bit unsightly, but there is a method of 'hiding' the connection which is generally accepted by CIDECT, AISC and ISO illustrated below.

This works with the options illustrated in Figs. 2 and 3. The cover plates are defined as non-structural and are formed by cutting a profile in half wrapping around the joint. They are cut from a profile size matching that of the incoming beam.

They may be site welded after erection or alternatively, site bolted to tabs welded to the inside of the incoming beam profile. Either way, it's a lot of site work and should only be used at the discretion of the architect or engineer.

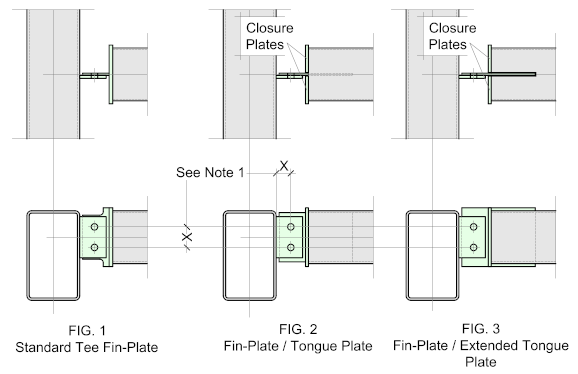

Connecting Open Section Beams to a Hollow Section

Connecting open section beams to a hollow section beam is much simpler, there is nothing to be done to the incoming beam except provide for the holes in the beam web to make the connection. The fin plate itself may be simply welded to the face of the hollow section supporting beam, as shown in fig. 7, or to counter the effects of the eccentricity (and resulting moments) the fin plate may be fitted into slots cut into the beam and welded.