There are basically 3- types of seating connections in common use, they include:

- The conventional Beam to Column Seating seat, where the beam is fastened perpendicular to the column.

- The Corbel, where the beam is fastened parallel to the column.

- The beam-to-beam crossover, where one beam sits at an angle on top of another.

- The Column Cap, where the Beam sits on a column cap plate.

The use of seating connections offers a number of advantages:

- They are simple and economical to fabricate

- The seat provides a support for the incoming beam while the erector aligns the connection

- The clearance between the beam-end and the column should be approximately 10-20 mm – this increased clearance makes erection easier.

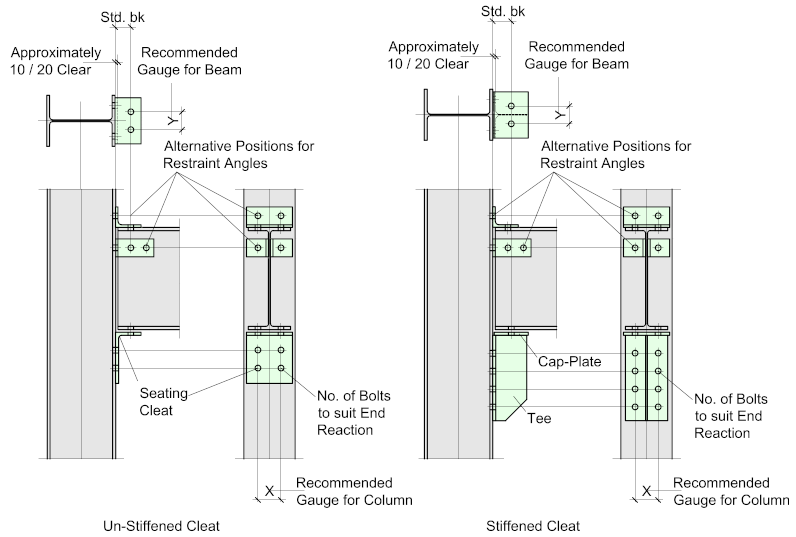

Beam to Column Seating Cleat

The seating cleat may be stiffened or unstiffened - as you would expect, the unstiffened cleat would be used for lightly loaded connections (usually for beams less than 300 mm deep). The seat itself would be fabricated from a standard rolled angle which is shop-bolted or welded to the column, upon which, the beam sits.

The stiffened cleat would be used for heavier connections - it may be fabricated from 2-angles fastened back-to-back, or as illustrated, from a standard Tee and cap-plate.

The Clearance Gap between the column and beam should be approximately 10 mm for beams < 600 mm deep, increasing to 20 mm for larger beams.

To prevent excessive rotation at the joint, restraint angles may be bolted to the top flange or the web of the connecting beam as close to the top as practical. This may compromise the flexibility of the joint by offering some Moment Resistance, but provide the angles are thin enough and the bolt spacing sufficiently wide, it should generally be OK - check this with the responsible engineer.

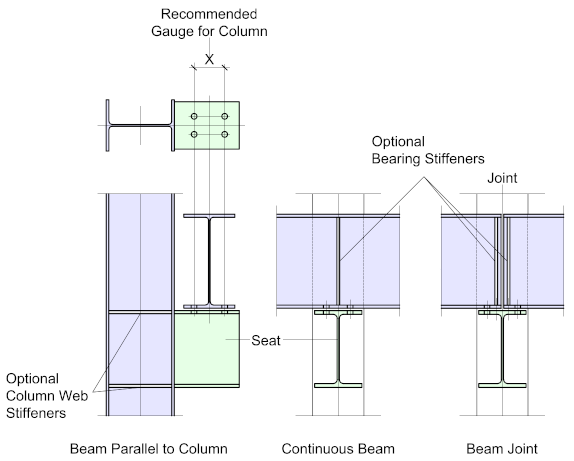

Corbel - Beam Paralell to the Column

The Corbel is usually fabricated from a standard hot-rolled section which is either shop-bolted or welded to the column flange. For general beam to column connections it's sometimes used together with Concrete Composite Floors where the column is set outside the floor. But more commonly, it's used where the beam is acting as a Crane Girder.

In such cases, there may be a significant moment applied to the column due to the eccentricity of the connection, in which case it will likely need to be stiffened with Web Stiffeners

The beam may be either continuous or may be joined at the Corbel, in which case Bearing Stiffeners may be required. It should be noted that at the beam joint, the beams themselves should not be connected. For more information on this and crane beams in general see Crane Girders

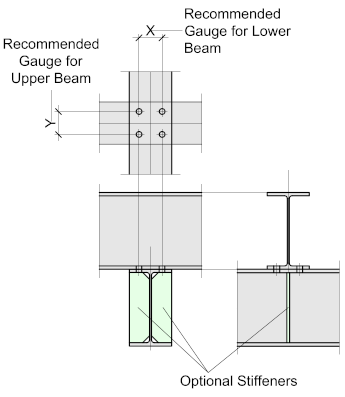

Beam-to-Beam Crossover

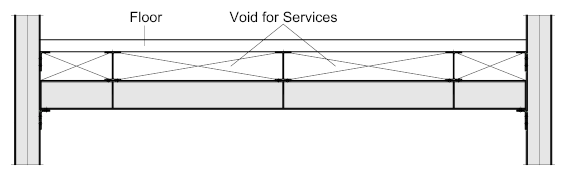

The Crossover connection is where one beam sits on top of another, they may cross at any angle relative to each other, but most often at right-angles.

It's common practice to fit Web Stiffeners to the lower (supporting) beam to prevent web buckling.

The bolt centers are determined by the standard, or workable gauges of the connecting members.

This arrangement is often found in multi-storey buildings where the bottom flange of the lower beam forms the ceiling of the floor below and the top flange of the upper beam forms the floor.

The void created between the two may then be used to accommodate services such as plumbing and electrical.

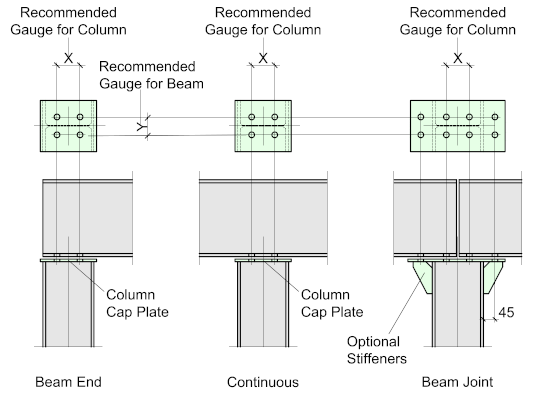

Column Cap Connections

Where a beam sits on top of a column, it's said to be a Cap Connection.

A cap-plate is shop-welded to the column upon which the beam sits. The connection may be at the beam-end, continuous, or at a beam joint.

As with the Corbel, it's commonly used when the beam is acting as a Crane Girder and the same limitation apply. For more information on this refer to Crane Girders.