Shear walls may be constructed from steel plate, reinforced concrete, or masonry, and are usually to be found in structures built is seismically active zones.

A shear-wall could loosely be described as a solid infill brace, often placed within the confines of the structure to assist the primary stabilizing system located at the periphery.

Shear-walls located internally will require careful placement as they will inevitably limit floor access, but if that can be overcome they are a very effective stabilizing option.

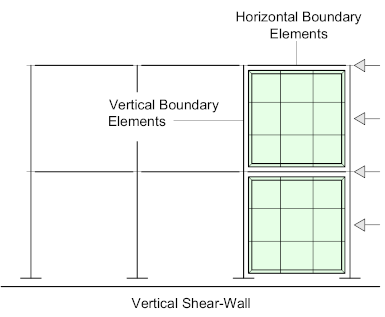

The effectiveness of a shear-wall is only as good as the bond between the wall and the vertical columns and beams, which are designated the horizontal and vertical boundary elements.

A typical shear-wall construction can be viewed as a vertical girder, with the vertical boundary elements forming the flanges, the horizontal boundary elements, acting as stiffeners, while the shear-wall infill acts as the web.

The shear-wall, like vertical bracing, should extend the full height of the building.

Steel-Plate Shear Walls

Steel-Plate shear walls may be stiffened or unstiffened depending on their span and the magnitude of the forces and may be either bolted or welded to their respective boundary elements.

A site-bolted steel-plate shear-wall would typically comprise of the steel panel bounded on all 4-sides with flange-plates, which may be either fitted to the structure on site, or more commonly shop-bolted to the beams and columns and erected as a sub-assembly. Due to the tight tolerances involved, site-fitting can often be problematic.

Sometimes, the shear-wall is to be site-welded to the beams and columns, which requires mating-plates to be shop-welded to the boundary elements in order to make the weld. This would provide the most effective bond for the shear-plate, but it’s a time-consuming exercise and can prove to be costly.

Stiffening a shear-plate can involve longitudinal and transverse stiffeners shop-welded to the plate, or diagonal bracing.

Composite Steel / Concrete Shear Walls

Reinforced concrete shear walls incorporated into steel structures are, in this case, formed by re-useable steel shutters temporarily attached to the vertical steel columns of the structure. This method of construction is not common today as it can be costly and time-consuming and requires the coordination of various trades on site which can sometimes be troublesome.

A composite shear wall where concrete is poured between a double-skin of permanent steel plates is sometimes employed, but due to its prohibitive cost, is rarely used.

Shear walls with pre-cast concrete panels fastened each side of a steel plate, which in turn is fastened to the vertical columns has been used with apparent success.

A structure that is a combination of steel and concrete, where the steel structure is supported from its concrete elements, is not considered in this publication as a shear-wall (see Leaned-Frames)

Masonry Shear Walls

Masonry shear walls are generally found in low rise or single storey structures which offer a reliable vertical stabilizing element, combined with a pleasing appearance. Windows and doors can be built into the shear-wall provided the openings are reinforced with lintels or other structural elements.

The masonry, which may be either brick or block is usually fastened to the steel columns by means of key-plates (or ‘Twigs’) site welded to the columns as the building work progresses.