Steel hollow sections have until recently been used almost exclusively for truss girders, bridge girders and in recent examples, columns, taking advantage of their inherent properties when axially loaded in tension and compression. The use of hollow sections as beams in frame structures subject to bending moment conditions is a fairly new application and their connections, whether they be end-plates, angle cleats or fin-plates have not yet been studied enough to allow for the preparation of definitive specific design methods. Up to now, the myriad of publications and studies on this subject has largely been developed by independent study groups and organizations.

We mention this because there is no definitive selection process available for the structural detailer, we can only refer to what has been done before in line with what we consider to be best practice. Therefore, the subject matter put forward in this series of articles should only be considered as a guideline, taking into account personal research by the author and practical field experience.

Bolted beam-to-beam connections using hollow sections are not that common – if they are done, they tend to be made from a welded sub-assembly which is then bolted to the supporting beams. This means that the sub-assemblies are prefabricated in the workshop ensuring greater accuracy and quality while keeping the site-bolted connections to a minimum – thereby reducing time spent on erection.

Bolted beam-to-beam connections using hollow sections are not that common – if they are done, they tend to be made from a welded sub-assembly which is then bolted to the supporting beams. This means that the sub-assemblies are prefabricated in the workshop ensuring greater accuracy and quality while keeping the site-bolted connections to a minimum – thereby reducing time spent on erection.

The more common arrangement is to connect open section beams to the hollow section supporting members, this is generally more efficient both structurally and practically - and only in those cases where the capacity of open sections is reduced by lateral buckling do hollow sections offer an advantage.

Thus, a typical arrangement would be to use the hollow sections for the outside shell of the structure where they would be visible and provide a pleasing appearance – while the internal floors would be open sections and hidden beneath the floor membrane, which may be either concrete or steel.

Having said that, bolted connections between hollow section beams do occur, but they are usually limited to single storey, lightweight open frames. Such connections are usually limited to one of 3 options: End-Plates, Angle Cleats and Fin-Plates.

Each of these options will allow for the use of Through-Bolts or Blind-Fixings.

Through-Bolts are the simplest and easiest of the options – they are generally more forgiving as the joint is easily accessible and will allow for minor adjustments during site erection. In the unfortunate event of the connections not lining up at all due to detailing or fabrication errors – they can be rectified more easily, (don’t mention that to the erection crew though)

Blind-Fixings require a high level of fabrication accuracy and can be more difficult to erect on site as many of the options require special tools – but the resulting connection is more discrete and will, in most cases, keep the architect happy.

For more information of these bolting options and links to a number of suppliers and resources go to Fastener Options.

End-Plates

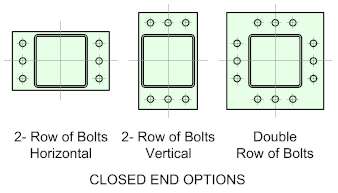

As a general rule, end-plates will be welded to the end of the incoming forming a closure plate referred to as a Closed-End. The end-Plate may be configured to be two-sided (with the bolt holes being vertical or horizontal) or 4-sided – the most common being the two-sided option. The end plate thickness is dependent on the prying action of the joint, but generally should not be less than 6 mm – 10mm being widely used.

If the beam is to be galvanized after fabrication, vent holes should be provided to allow for the ingress of the molten zinc and expulsion of gasses.

(Information on detailing hollow section steelwork to be galvanized will be covered in a future article)

Angle Cleats

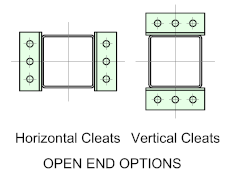

Angle Cleats may be welded or shop-bolted to the end of the incoming beam which may be configured horizontally or vertically depending on the application. The main difference between cleats and end-plates is that with cleats, the beam ends are open – referred to as Open-Ended. Open ended connections are ideal if the beam is to be galvanized inside and out, but if exposed to the elements in harsh environments then there may be the possibility of internal corrosion, which is the Achilles-heel of all hollow section profiles.

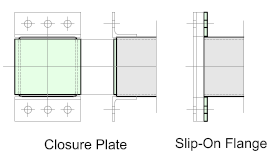

If you wish to use an end-plate with an open end, it will be necessary to open the inside of the plate to form a slip-on flange – this is a costly option which is difficult to justify when comparing it to the use of angle cleats. Likewise, an open end can be closed with a closure plate. When adopting this method, the closure plate should not interfere with the positioning of the cleats and should not extend beyond the face of the hollow section to which the cleats are fitted. Again, it would be difficult to justify this option when compared to the use of an end-plate.

If you wish to use an end-plate with an open end, it will be necessary to open the inside of the plate to form a slip-on flange – this is a costly option which is difficult to justify when comparing it to the use of angle cleats. Likewise, an open end can be closed with a closure plate. When adopting this method, the closure plate should not interfere with the positioning of the cleats and should not extend beyond the face of the hollow section to which the cleats are fitted. Again, it would be difficult to justify this option when compared to the use of an end-plate.

Fin-Plates

Fin-plates are not always the most cost-effective option when connecting hollow section beams together, they often require a lot of welding, particularly to the incoming beam and the result is often unsightly. There has been research conducted into creating a ‘hidden’ connection which is widely accepted, but though it does its job, it is an expensive time-consuming solution and used mainly for spliced connections.

Fin-plates come into their own when connecting an open section beam to a hollow section, which is by far the most widely used application. It’s relatively inexpensive to fabricate and straightforward to erect at it will allow the use of Through-Bolting and all the advantages that come with it.

All of these connection options are discussed separately with typical examples under their separate headings. For more information refer to the following links:

- HSS Beam-to-Beam Connections using End-Plates / Cleats

- HSS Beam-to-Beam Connections using Fin-Plates

- HSS Beam-to-Column Connections using End-Plates / Cleats

- HSS Beam-to-Column Connections using Fin-Plates