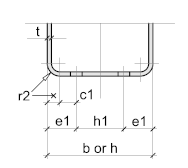

The blind bolt hole centers are a function of the outside corner radius (r2) of the hollow section profile. To determine the bolt hole centers it's necessary to work from the outside-in, therefore, dimension (e1) is a function of the corner radius + clearance for the blind fastener (c1) - this will vary depending on which fastener is chosen, but if you allow for (c1) to be equal to the bolt diameter than it will be found to work for most, if not all, the listed options. But a note of caution here! - check this against the manufacturer’s documentation - Refer to Fastener Options

The blind bolt hole centers are a function of the outside corner radius (r2) of the hollow section profile. To determine the bolt hole centers it's necessary to work from the outside-in, therefore, dimension (e1) is a function of the corner radius + clearance for the blind fastener (c1) - this will vary depending on which fastener is chosen, but if you allow for (c1) to be equal to the bolt diameter than it will be found to work for most, if not all, the listed options. But a note of caution here! - check this against the manufacturer’s documentation - Refer to Fastener Options

Therefore, (e1 x 2) / b or h will give the minimum bolt hole centers. This value should then be rounded down to the nearest round figure.

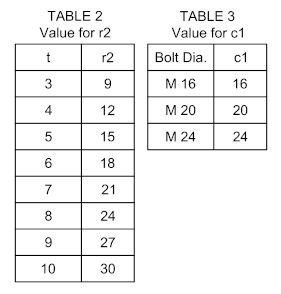

The hollow section outside corner radius varies according to specific manufacturers and regions - some are quite specific while others leave room allowing different manufacturers to provide their own standards. Table 1 - indicates a few of these variations according to standards set by CEN (EN), Australia (AS) and the (AISC). In the interests of standardization, it's probably a good idea to base them on the worst case, which in this instance is the AISC which recommends the corner radius should not be greater than 3 x t (Wall Thickness) - based on this figure, it should enable the detailer to develop an all-encompassing standard. (See Tables 2 and 3 below).

The hollow section outside corner radius varies according to specific manufacturers and regions - some are quite specific while others leave room allowing different manufacturers to provide their own standards. Table 1 - indicates a few of these variations according to standards set by CEN (EN), Australia (AS) and the (AISC). In the interests of standardization, it's probably a good idea to base them on the worst case, which in this instance is the AISC which recommends the corner radius should not be greater than 3 x t (Wall Thickness) - based on this figure, it should enable the detailer to develop an all-encompassing standard. (See Tables 2 and 3 below).

Note that these are only suggested standards, which though they may be applied with reasonable confidence they should be confirmed with the responsible engineer.

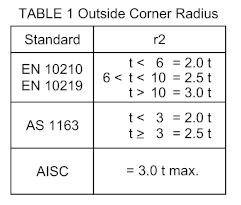

Table 2 shows suggested values for (r2) based on 3 x the hollow section wall thickness.

Table 3 shows suggested values for (c1) based on the bolt diameter