Under normal circumstances it's generally unnecessary to strengthen a beam - it's an expensive and time-consuming exercise and generally avoided, however, there will always be occasions where it's necessary.

Strengthening the Beam Flange

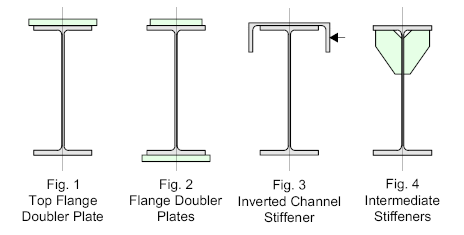

The beam flange may be stiffened to improve the bending capacity of the beam, and to provide resistance to lateral forces.

Fig 1 – shows a typical top-flange doubler-plate acting as reinforcement to the compression flange. Such stiffening would normally run the full length of the beam

Fig. 2 – Shows doubler-plates welded to both the compression and tension flanges. It should be noted that when doubler plates are configured in this manner, the top plate should ideally be narrower than the top flange, while the bottom plate should be wider than the bottom flange. This is to facilitate down-hand welding thus negating the need to turn the beam in the workshop.

Fig 3 – Indicates an inverted channel flange stiffener which apart from providing additional bending resistance (though not as efficient as the plate) provides restraint against lateral forces. Stiffening arrangement of this type are commonly found on Crane-Beams to counteract the lateral forces generated by the movement of the crane gantry.

Fig. 4 – indicates an intermediate flange stiffener generally located at points of load to prevent deformation of the top flange. Such stiffeners are also generally to be found on Crane Beams to prevent top-flange deformation created my any slight misalignment of the crane rail.

Strengthening the Beam Web

Strengthening the beam web will improve the beam’s shear capacity, to achieve this, there are two options:

Fig. 5 – Indicates web doubler-plates which would be located at points of high shear and will not necessarily run the full length of the beam. To run the full length, it would be found to be more economical to use a Fabricated Plate-Girder with a thicker web-plate.

Fig. 6 – Indicates transverse web-stiffeners which may be welded to one or both sides of the beam web. The design and selection of these stiffeners would depend on what they are intended to do.

If they are to act as web stiffeners to prevent web-buckling they would typically be welded to the beam web and either welded of fitted to the underside of the top (Compression) flange whilst stopping short of the bottom (Tension) flange by a distance of 4 x the beam flange thickness or 50 mm.

Should they be designed to act as bearing stiffeners, they should be located at the point of bearing on the beam flange (Compression-Flange) and welded. The stiffener should be extended to the full depth of the beam to the inside of the tension flange, and as near as possible, fitted.

Transverse web-stiffeners are examined in more detail under– Strengthening a Welded Plate-Girder