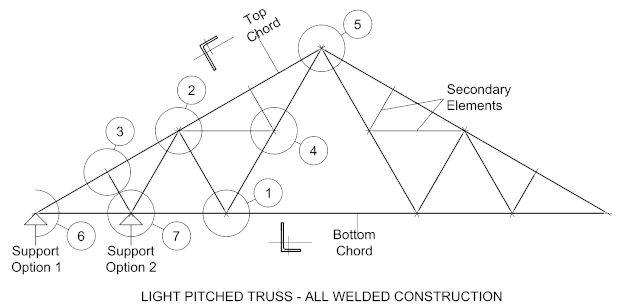

In this example, we show an all-welded pitched truss (or Fink Truss)

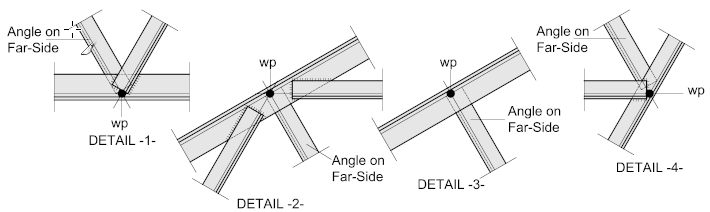

For All-Welded trusses formed from angles, the work points should be established from the centroids of the members. In order to achieve maximum weld contact between the members, the diagonal lacing members are located on the far-side of the chords.

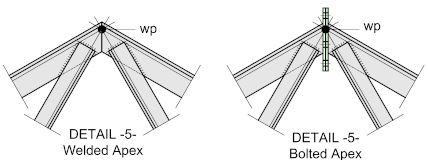

The apex joint may be either welded or bolted. For long-span trusses the bolted option may be preferable

End Support Options

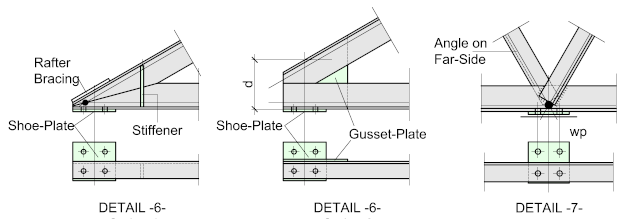

DETAIL -6- (Support Option -1-) illustrates a shoe-plate welded to the underside of the bottom chord. This is probably the most efficient of the two options as any eccentricity is kept to the minimum.

DETAIL -6- (Support Option -2-) is the more simple to fabricate but the eccentricity calculated from (d) should be checked by the responsible engineer.

DETAIL -7- shows a typical connection for a cantilevered truss. A simple base-plate is welded to the underside of the bottom chord which should align with a node.