Connecting to a Steel Floor – Bottom Seating-Connection

Stairways connecting to steel floors are commonly found in emergency fire escapes and industrial environments where they would provide access between floors, and to and from platforms and walkways.

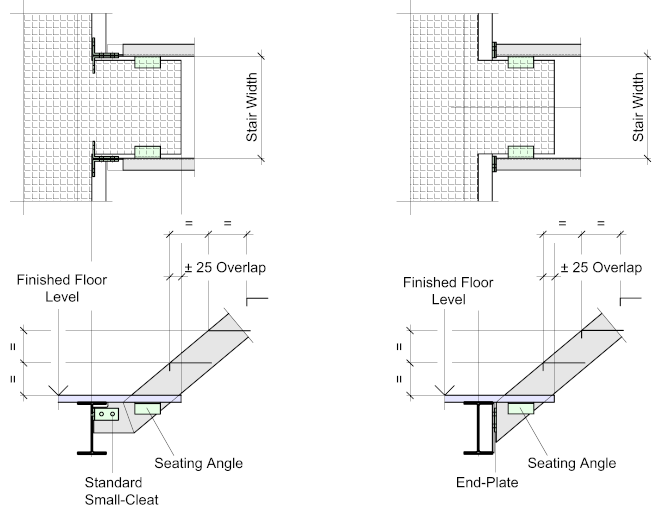

The specific application will determine the most suitable connection type, of which there are 2 principal options:

The connections to the steelwork may be either a Cleat (as indicated) or and end-plate - however, using an end-plate will reduce the adjustment.

The flooring would be profiled around the base of the stringers and connections ensuring a minimum overlap to the nose of the first tread of approximately 20 mm.

The same principle of measuring the rise from the top of the finished floor, whether it be a raised pattern steel plate or open grid.

Once again, the stringer base should be cropped back so that it protrudes from the stair nose by approximately 25 mm to eliminate any trip hazard.

The same principle of allowing levelling packs under the stringer base applies.

This is a very common connection type being the most cost effective in terms of fabrication and erection, but on narrow platforms with heavy foot traffic, the base can intrude inside the walkway handrail line causing an obstruction. For this reason, such connections are not desirable for emergency escape routes where a rapid descent is likely.

This connection type should only be considered in industrial environments where only light foot traffic is anticipated for inspection and maintenance purposes.

Connecting to a Steel Floor – Bottom Side-Connection

The second option is to connect to the web of the supporting beam, it will eliminate any potential trip hazard, is far easier to descend, and simply looks right. However, it’s costlier to fabricate and more difficult to erect because it does not offer the same level of adjustment due to the tighter tolerances involved.

Another point to consider is that this type of connection with take up more horizontal space, and in situations where space is limited, it may be problematic.

When connecting to the web of the supporting beam the stair stringer may be ‘mitered’ or simply cut to suit the angle of the stair. Either way the same basic principles apply, the riser height is measured from the top of the finished floor, and the flooring must extend between the stringers to give the required overlap. To achieve this, seating angles must be fitted to the inside of the stringers to support the flooring.

This connection type is not the most economical in terms of fabrication, but it provides an excellent lead-in to the stairway, the handrail can seamlessly follow the stair route, and there are no encumbrances that could cause potential trip hazards.

The connection of the stringers to the supporting beam may be any of the Flexible Connection types.