Stair treads are usually a bought-out item, though some fabrication workshops make their own, it’s generally not cost effective. There are numerous suppliers whose products conform to the necessary codes and specifications which means they can be used with confidence.

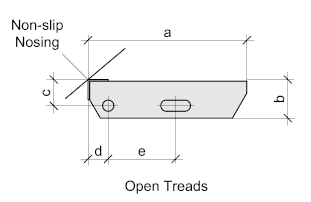

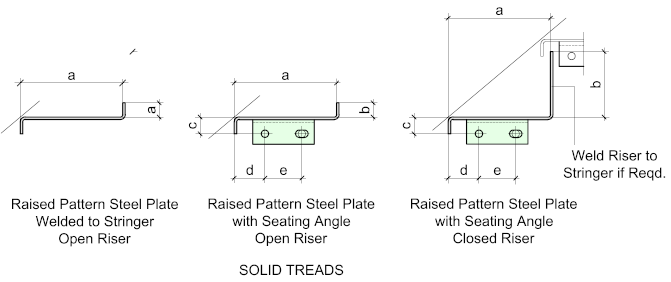

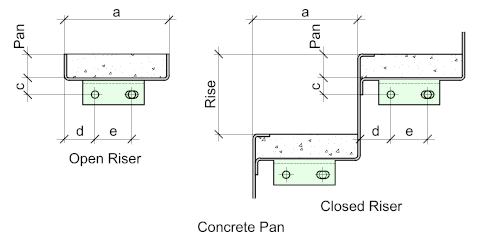

The key dimensions for stair treads include – the tread depth (a) / side-plate depth (b) and the position of the fixing holes (c, d, and e). Notice that the rear fixing hole is always slotted. The hole diameters will be according to the manufacturers specification

Though there are many types available they can be divided into 2 categories: Open grid and steel plate with or without closed risers.

Open Grid Stair Treads

Open-grid treads are most commonly used in an industrial environment where their see-through properties make them ideal for platforms and walkways.

They also have the advantages of allowing light to pass through allowing good visibility, and do not seriously impede airflow which is an advantage in closed environments.

Open-grid stair treads should be fitted with non-slip nosing’s, usually made from a raised pattern steel plate and fitted to the leading edge. The nosing should be at least 25 mm deep and not protrude more than 3 mm above the tread. The nosing also doubles as a ‘sighting-edge’ which is essential in all properly designed stairways. They also have the advantage of being self-cleaning, preventing the build-up of hazardous debris or liquids.

Open grid stair-treads are generally of the open-riser type and are usually bolted to the stringers making them easy to install and maintain.

However, it’s these properties that make them unsuitable for public access areas and emergency escape routes where the wider population must be considered, they are not suitable for women in high-heel shoes and can prove to be un-nerving to people not used to heights, in such cases, solid treads are preferable.

Solid Stair Treads

Solid stair-treads are usually fabricated from bent, raised pattern steel plate and may be bolted or welded to the stair stringers. They provide the option of open or closed risers making them flexible and suitable for a wide variety of applications. However, when located outside and exposed to the elements they are susceptible to corrosion and must be regularly inspected and maintained.

Solid Treads are commonly used for Fire and emergency escape routes

Note! The values for a and b will depend on the slope of the stairway. For more information go to Calculating Stair Tread and Riser Dimensions below.

Values for c, d and e are flexible and should be set-out to suit the stringer profile

Concrete Pans

Concrete pans come in a wide variety of shapes and sizes, generally, they are fabricated from 5 / 6 mm plate and are purpose made for a particular application. They may be bolted (as illustrated) or welded to the stringers and once set, are filled with a smooth concrete.

They are becoming increasingly popular among architects due to their aesthetic qualities

Calculating Stair Tread and Riser Dimensions

The total rise and total distance are always measured from the top and bottom finished floor levels, which may be either a concrete, steel, or open grid. In the event of a concrete floor at the top of the stair a nosing must be cast into the concrete to prevent wearing of the corner.

Generally, the riser is determined by dividing the step rise by the total rise, which will give the resultant number of steps. Often, this is an odd number, so common practice is to round off the calculated number of steps to the nearest whole number, dividing that into the total rise. For example:

Total rise = 2 500.

Desired step-rise = 175

Therefore: 2 500 / 175 = 14.28 (Round off to 14)

Therefore: 2 500 / 14 = 178.57 (Round off to 179)

Therefore: we have 14 risers’ x 179 = 2 506 giving an odd riser with a 6mm difference

Common practice is to place the odd riser at the bottom, which will result in the following riser dimensions:

First (bottom) riser = 173 + (13 x 179) = 2 500

Note!

Tread dimensions marked thus * are for open risers and are calculated from (Going + 25) and is a nominal dimension only, round off to the nearest standard size

Slope angle is measured from the horizontal plane

|

Stair Tread and Riser Dimensions |

|||||||

|

Slope |

Riser | Tread | Slope | Riser | Tread |

Going |

|

|

22° |

150 | 371 | 34° | 180 | 277 | - | |

|

23° |

150 | 353 | 35° | 185 | 274 |

- |

|

|

24° |

155 | 348 | 36° | 190 | 261 |

- |

|

|

25° |

155 | 332 | 37° | 190 | 252 |

- |

|

|

26° |

160 | 328 | 38° | 195 | 250 |

- |

|

|

27° |

165 | 323 |

|

||||

|

28° |

165 | 310 | 39° | 195 | 266* |

241 |

|

|

29° |

170 | 307 | 40° | 195 | 257* |

232 |

|

|

30° |

170 | 294 | 41° | 195 | 249* |

224 |

|

|

31° |

175 | 291 | 42° | 200 | 247* |

222 |

|

|

32° |

175 | 285 | 43° | 200 | 239* |

214 |

|

|

33° |

175 | 280 | 44° | 200 | 232* |

207 |

|

|

45° |

200 | 225* | 200 | ||||

Stringers

Stair stringers are most commonly fabricated from flat steel plate or standard rolled channel sections, the common sizes being; 180 x 10 Flat plate, or 180 x 70 channels, these sizes are generally suitable for most stairways at angles of between 38 and 45 degrees, but for long spans, shallow angles, and heavily loaded stairways they should be purpose designed to meet structural requirements.

For deep stair treads the 180 channel may not be able to accommodate the tread bolt spacing (e) in which case the stringer size may need to be increased.

‘Miters’ and ‘cranks’ are usually welded while the stair treads may be either bolted or welded.