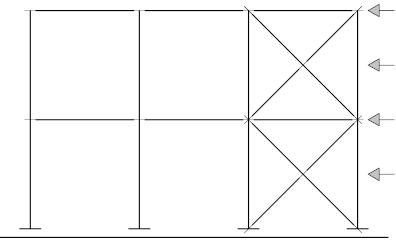

Typical Vertical Bracing Connections Girder (Bridge) Trusses

This type of connection is commonly found in Girder Trusses, particularly Bridge Girders. The horizontal beam(s) may be orientated with the flanges top and bottom or rotated through 90° with the flanges to the side. The advantage with the latter is that the beams and bracing members can be of the same section making it […]

Typical Vertical Bracing Connections Girder (Bridge) Trusses Read Article »