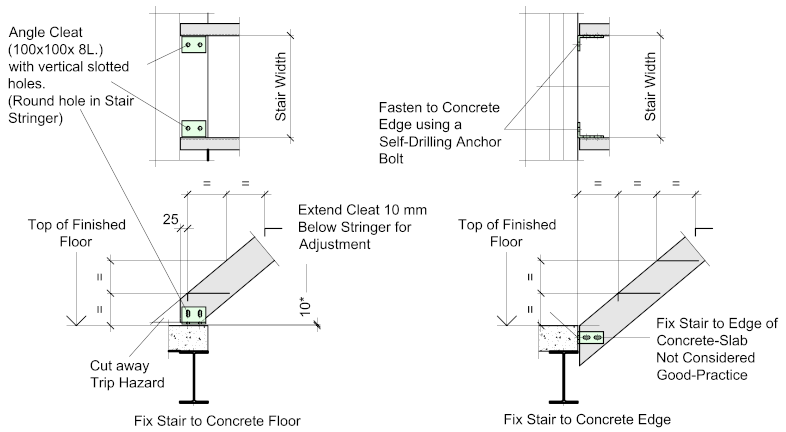

Probably the easiest way to connect a stair to a concrete floor is to sit it on top and fasten it directly to the concrete.

The limiting factor here is that the concrete floor must be in place before the stair can be installed. This generally doesn’t present a problem if the stair is to be fitted into an existing structure, in which case this would be the most common fixing method, provided the base of the stair does not intrude into a public access area or walkway.

Another option is to fasten the stairway to the edge of the slab thus removing the obstruction, but this is generally considered to be bad-practice as the concrete edge is likely to be uneven and may not provide an adequate bond.

However, if the stair is being fitted to a new build where the civil construction is following the steel erection, it may be necessary to attach the stairways to the steelwork prior to pouring the concrete floor decks, or alternatively fix a steel spacer to the top of the steelwork, pre-drilled to accept the stair

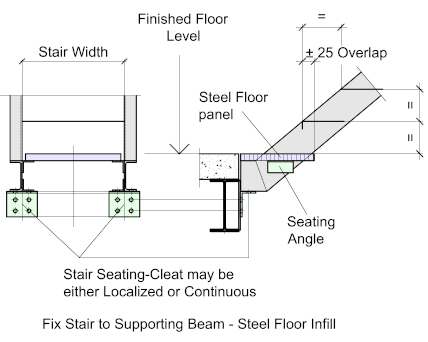

There are 2 commonly applied methods to attach the stair to the supporting steel of a steel / concrete composite floor.

Connecting to Supporting Steelwork Before the Floor has been Cast in Place

Firstly, the bottom of the stair stringer would be ‘cranked’ and mounted on a seating angle which would be fastened to the support beam. This will require a Tee or plate to be shop-fitted to the beam

The gap created between the floor edge and the first stair tread would be covered by means of a steel floor plate or open-grid type flooring mounted on a seating angle welded to the inside of the stair stringers.

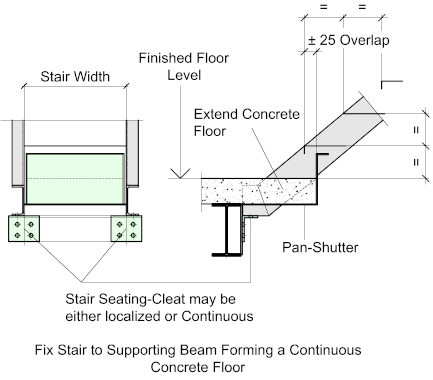

This solution, though relatively simple does not lend itself to commercial buildings where architectural considerations must be taken into account, a solution more pleasing to the eye, which the architect would probably insist on would be to substitute the steel flooring with a pan-shutter and continue the concrete floor to form the landing.

This is a very neat solution as it provides what is effectively a continuous floor and a well-defined landing.

The Pan-Shutter is usually formed from a bent-plate and may be either bolted or welded to the inside face of the stringers forming a permanent shutter for the concrete floor.

The stair level may be adjusted to suit on-site by placing ‘packers’ between the seat and the bottom of the stair while the finished floor level is determined by the concrete or screed.

Pan-Shutters are fairly straightforward to custom-fabricate as the slope of the stair has little effect on the dimensions, alternatively, proprietary pan-shutters can be bought-out from numerous suppliers.