A structural bolt typically has a partial thread, the unthreaded portion is the shank, which when added to the thread length gives the overall bolt length. The thread length is a function of the bolt diameter and length, which for the most part is standardized across the range of bolts – but it’s always wise to check against the particular standard. There is a swell of opinion that favors the use of fully threaded bolts, the advantage being that it’s easier to standardize the bolt lengths for use on a project – but in general, partially threaded bolts remain the de-facto standard. We’ll look at this again later in this article.

There are 3 options to consider when calculating the bolt length. each has advantages and disadvantages which depend on the criticality of the connection and the bolt grade or class being used.

Option 1 – is the most common approach because it’s simple, and keeps the bolt length down to a minimum. The one drawback is that the bolt thread lies in the shear plane of the connection which means a reduced shear value must be assumed to cater for the reduced cross section area of the bolt. The detailer should ensure that this has been taken into account before adopting this method – if in any doubt, check with the responsible engineer

Therefore, the bolt length is calculated by adding together: Grip + A + B

where A is the nut and washer thickness – if no washer is used, then leave it out. B is the protrusion should and ideally be between 0 and 10 mm (Optimally 5 mm) – then round up to the nearest Preferred Size.

Option 2 -is necessary if thread is to be kept outside of the shear plane. This will result in a longer bolt and protrusion – it’s structurally more efficient in that the full shear value of the bolt can be assumed. In some cases, it may allow you to use less bolts – but this is not necessarily an advantage as it will have an impact when considering Standard Connections

This is slightly more work to establish because the bolt must be selected so that the length of the shank is greater than the thickest component of the connection. The only way to establish shank length is the deduct the Thread Length from the overall bolt length.

The value X should be equal to or greater than the Thread Runout

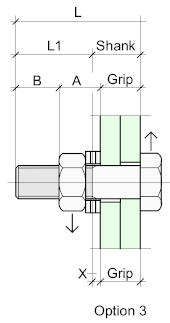

Option 3 – may be considered slightly ‘over-the-top’ but some companies adopt this method, the idea is that the entire bolt thread is outside of the connected parts, As with Option 2 – the shank length is determined by deducting the thread length from the overall length – this will result in an extra-long bolt where in many cases the thread will terminate outside of the grip, therefore filler washes will need to be added.

Also, as with Option 2 – the value X should be equal to or greater than the thread Runout