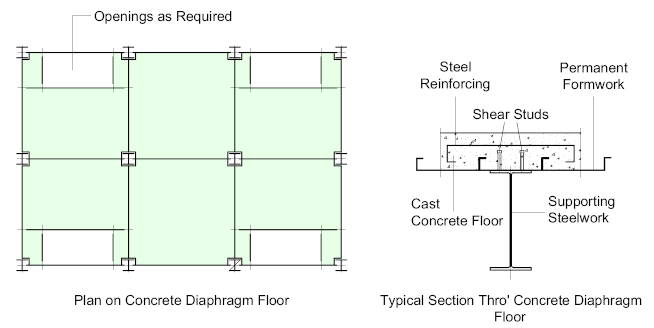

Diaphragms are usually incorporated into Multi-Storey commercial structures and typically consist of Profiled Steel Decking with a reinforced concrete floor cast in-situ. The decking not only acts as a permanent shutter, but it also provides sufficient shear-bond with the concrete by means of the shear-studs, so that when the concrete has gained sufficient strength the two materials act ‘compositely’, hence it is known as a ‘Composite Floor’

The composite action is achieved by means of shear-studs which are welded through the decking to the top flange of the supporting steelwork by means of thro-deck welding. These shear studs provide sufficient shear connection between the concrete and the steel floor so that they act together structurally. Openings may be incorporated into the floor for stairways, elevator shafts, and service wells.

Alternatively, pre-cast concrete floor-slabs may be placed on the floor steelwork, which are then bonded to the steel beams to form the composite action, and ‘screeded’ after installation to form the ‘finished-floor’. This type of floor is quick to install but is usually limited to low-rise residential or commercial buildings. There are numerous types of this floor available commercially, and technical information is freely available.

Raised Pattern Steel Plate when welded to the top flange of the supporting steelwork can also, to some extent, act as a diaphragm, it’s usually applied in an industrial environment where its non-slip properties make it ideal for walkways, stairways, and platforms.

Though it’s useful due to its relatively light weight and ease of erection, it’s rarely used a primary diaphragm because of its propensity to damage and corrosion, and unless it’s carefully maintained it could prove unreliable. Often, it’s used in conjunction with supplementary horizontal bracing