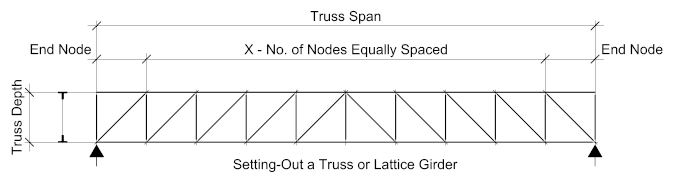

A typical Truss is comprised of the top and bottom horizontal members known as the Chords – the vertical members are either the Ties of Struts, depending on whether they are in Tension or Compression, while the diagonal members form the Lacing. The distance between the intersection points (known as the Nodes) of the Lacing and the chords form the Bays.

The depth of the Truss is measured from the tops and bottoms of the chords, while the span is the distance between the end supports.

The angle for the lacing members should be between 30° and 60° with 45° being the optimal – (This should be determined by the responsible engineer)

Ideally, the Nodes should be set out according to the Centroids of the members to ensure the most efficient distribution of the loads – which for –I- / -H- / and hollow section profiles are conveniently the geometric centers, but for channels and angles they are not. This is discussed further under Truss Connections

When setting-out the truss, it’s important that its done in a manner that is both Uniform and economical. This not only makes things easier for the detailer, but also the fabrication workshop and erection crews.

The first step is to ensure the inner bays (or Nodes) are equally spaced over the span. We say ‘inner bays’ because the span of the truss is determined by the manner in which its supported. Invariably as a result, the span will be an odd dimension. To compensate for this, the two end bays should be marginally flexible and will differ from the inner ‘standard’ bays’

Supporting a Truss

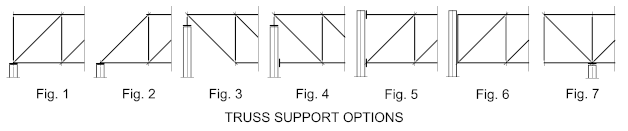

A truss can be supported in any number of ways with the most common as illustrated below. The length of the truss is determined by the centers of the support members which may be a column, beam, or concrete wall. A truss may also be supported from another truss for wide-span open areas unencumbered by additional columns.

Details of these options can be found under the respective truss details, links to which can be found at the bottom of this page.

Fig. 1 illustrates a simple bottom chord seating connection, site-bolted to the supporting member

Fig. 2 illustrates a similar connection commonly found in bridge girders - in such cases the support would sit on a concrete foundation.

Fig. 3 illustrates a truss supported from the top chord

Fig. 4 illustrates a truss with the top chord seated on the support member and the bottom chord bolted to a column by an end plate

Fig. 5 illustrates a truss supported by end-plates bolting to a column

Fig. 6 illustrates a truss continuously bolted through the vertical member to a column or another truss

Fig. 7 illustrates a cantilevered truss seating on a column.