Shared Bolts

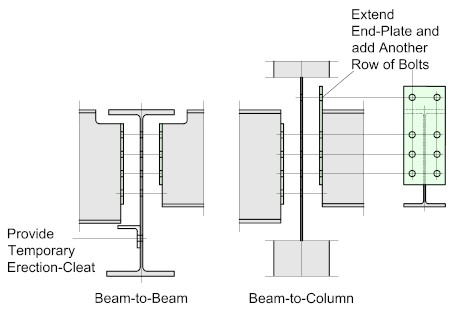

One factor to be considered with shared bolts is the thought that must be applied to the site-erection of the beams, where both beams must be held in position until at least some of the bolts have been installed. In most cases, especially with smaller beams this can be accomplished with a skilled erector with little more than a ‘Podger’, but for large heavy beams this can sometimes be difficult. Also, the site safety-officer may not be happy with anything but a ‘designed’ solution, hence it may become the responsibility of the draftsman to anticipate such difficulties and present a solution

The simplest solution is to provide a temporary erection cleat to allow one of the beams to safely ‘seat’ while the connection is to be tightened. This will work for beam-to-column connections and beam-to-beam provided there is sufficient space to accommodate the cleat.

For beam-to-beam connections where there isn’t sufficient space it may be necessary to modify the end-plate or cleat to accommodate an additional erection bolt.

See illustration right.

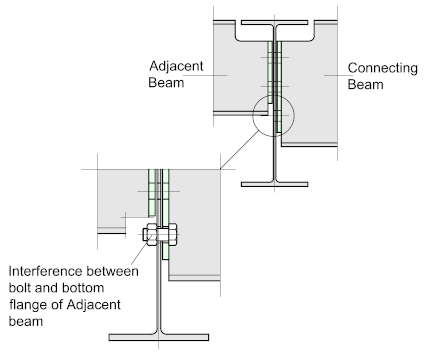

Bolt Interference

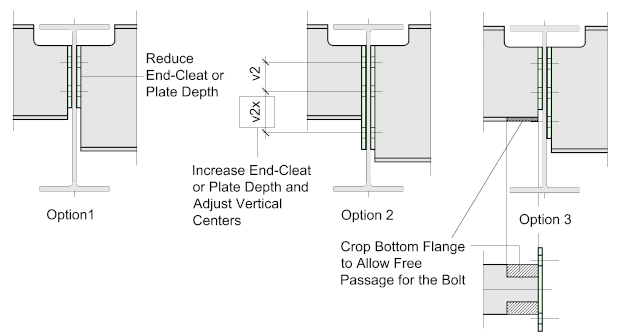

Bolt interference occurs when two adjacent beams of differing sections connect to a common web on the supporting member. In such instances it’s possible that the lower row of bolts on the larger section will interfere with the bottom-flange of the smaller. This is a very common occurrence, and one that’s very difficult to fix on-site so it’s important that these situations are identified at the detailing stage, and solutions presented.

This can occur with all connections that connect directly to the web of the supporting beam. If neither of the following possible solutions suggested below can be made to work, then it may be necessary to adopt a different connection option

Fortunately, being such a common occurrence there are a number of well-established and accepted solutions which are presented here as options:

Option 1 – is to reduce the size of the larger end-plate or cleat thereby removing the offending bolts altogether. This clearly the simplest solution but the connection must be checked to ensure the reduced capacity is still adequate.

Option 2 – Is to increase the depth of the End-Plate or Cleat while increasing the pitch of the offending bolts. This option will only work if the supporting beam is of sufficient depth to accommodate the increased bolt pitch. However, it will result in a ‘non-standard’ bolt-pattern.

Option 3 – is to strip the bottom-flange of the smaller section thus removing the obstruction. ‘Stripping’ the flange is not the same as Notching or ‘Coping’ the flange, stripping will not affect the shear capacity of the connection.

Another option which will not be seriously considered is to replace the offending End-Plate or Cleat with a Fin-Plate. Such an option will unnecessarily complicate the connection as it’s generally considered bad-practice to mix-and-match connection types.