Columns are stiffened mainly to improve their resistance to bending moments and are often used in conjunction with Moment Connections.

Careful selection of the columns and beams will often negate the need for strengthening of the connections, however, there will always be cases where it’s deemed necessary.

The method of strengthening is determined by the intended stiffness of the structure. Connections that are designed for Full-Strength are assumed to be ‘rigid’, while structures that require some flexibility, such as wind-moment frames would be considered to be semi-rigid. Therefore, the connection details and recommended strengthening are the responsibility of the responsible engineer.

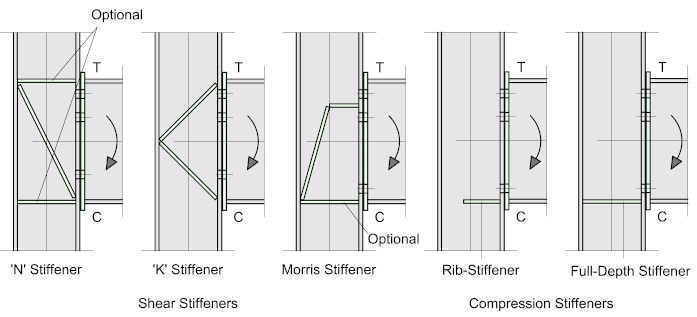

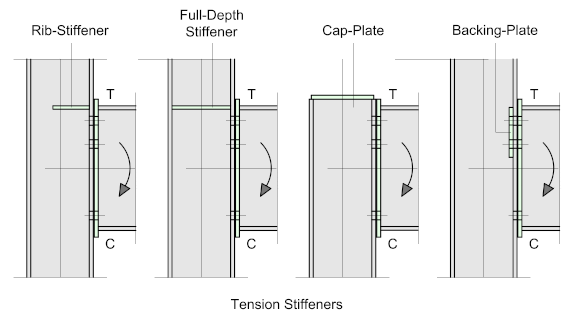

The stiffeners may be placed to improve the Tension, Shear and Compression capacity of the column

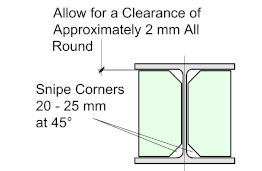

To ensure fitment of the stiffener between the column flanges allow for clearance of approximately 2 mm. all round - this will compensate for the mill rolling tolerances.

Additionally, snipe the corners of the stiffeners to ensure they will fit without intruding into the root radius of the column flange.

The following illustrations are typical examples of the column strengthening options in common use:

Tension Stiffeners

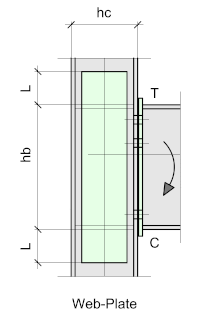

Web Plate

The length of the web-plate can be loosely determined by taking the depth of the incoming beam (hb) + (L), where (L) = 0.5 x the column width.

Shear and Compression Stiffeners