A Truss or Lattice Girder may be formed from almost any combination of steel sections including:

- Hot Rolled Sections

- Square, Rectangular or Circular Hollow Sections, and -

- Cold Formed Profiles

In this article, we'll look specifically at Hot Rolled Sections including: Angles, Channels, Tees and I / H profiles, both Bolted and Welded.

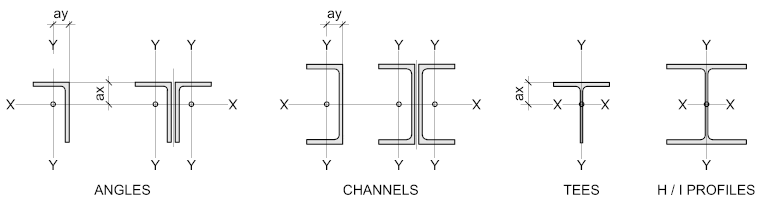

The one property all truss girders share in common (With the exception of the Vierendeel Truss) is that they are all of some form of triangulated configuration, with the component members intersecting at a common work-point or ‘Node’. When considering welded frames, the intersection-points are determined by the ‘centroids’ or ‘centers-of-gravity’ on the member sections which are designated as the ‘X’ and ‘Y’ axes.

Values for ax and ay will vary according to the section profile and size - refer to your steel tables

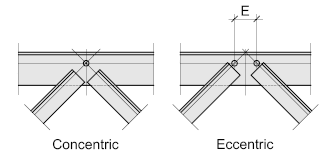

Any eccentricities at the ‘nodes’ will create moments at the joint which will mean the girder will not be analyzed as a straightforward pin-ended frame thus complicating the design.

Lightweight Welded Frames

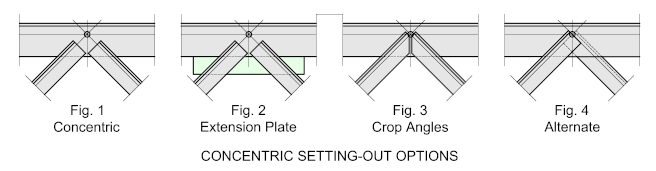

When setting-out a truss with lightweight angles, maintaining the node at the centroids can sometimes be a bit problematic. The main problem is ensuring there is sufficient contact between the chords and the lacing members to get a substantial weld. If the Chords are significantly larger than the lacing members, then this will usually be OK, but if they are not - then the overlap may be insufficient as can be seen in Fig. 1 in which case it may be worth considering a few options.

Fig. 2 indicates an extension plate which is welded to the toe of the chord angle ensuring the mating faces between the plate and the angle lacing are coincident.

Fig. 3 shows the possibility of cropping the lacing angles to ensure a snug fit. The gap between the members should be such that welds can be established.

Fig. 4 which is the simplest and most cost effective solution is the alternate the lacing angles each side of the chord leg. This will be most effective if the top and bottom chords are of the same size.

Bolted Frames

Bolted Frames require a different approach, though technically, its possible to use the same setting-out procedure as that for welded frames its difficult, if not impossible, to set the bolts on the centroids.

To overcome this, its standard practice to move the setting-out points to the centers of the profiles thus allowing sufficient clearance for the bolts.

This will create a minor eccentricity into the connection but the gusset plate will add additional reinforcing the the joint - negating any undesirable moments.