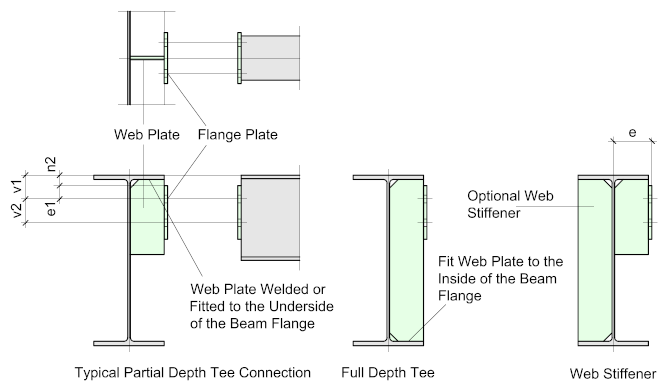

The Welded-Tee connection is the most expensive to fabricate of all the connection types, they typically comprise of a flange and web-plate formed into a Tee, which is then welded to the top-flange and web of the supporting beam. The Tee may also be fabricated from a Tee-Cutting of a standard rolled section, usually matching that of the incoming beam. Flexibility is maintained by the end-plate or cleat of the incoming beam.

The web plate may be either Partial Depth or Full Depth. The full depth Tee may be formed by adding a flange plate to a pre-existing Web Stiffener.

Due to the eccentricity of the connection, it may be necessary to add a web stiffener to the beam to prevent buckling due to the increased moment.

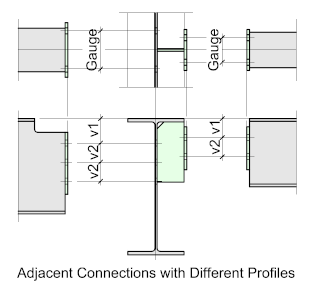

Tee connections are useful when adjacent beams connect to a common supporting beam with both having different bolt patterns. The Tee effectively separates the two enabling standard connections to be employed on both sides.

The alternative would be to design a special connection (usually at the smaller beam) to avoid any difficulties that may arise from Shared Bolts.

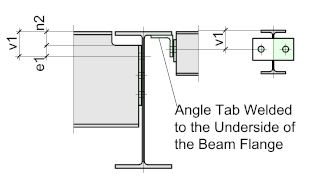

Another variation of the Tee Connection is the Welded tab - this may also be used when the bolt pattern of the incoming beam differs from the adjacent beam - it's also commonly used to fix handrail.

This is a simple and relatively low-cost solution to avoid the pitfalls of Shared Bolts