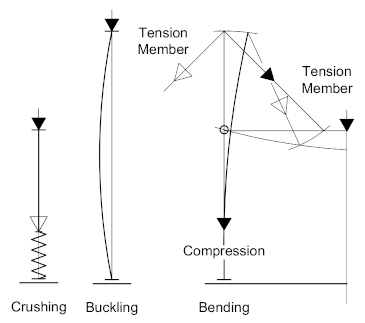

Columns are essentially compression members, but they may be required to resist lateral forces caused by wind and seismic activity. Additionally, they may be required to resist bending, especially in suspension structures where they act as ‘towers’ or ‘masts’ providing support for tension members. Bending may also be the result of eccentricity of the end-reaction in connecting beams. However, axial compression is normally the predominant effect.

Columns generally fail in one of two ways, Crushing, and Buckling.

Crushing occurs when the column is very short in relation to its cross-sectional area, under this condition, the failure of the column is due to a failure in compression of the material itself, by buckling and deforming perpendicular to its axis. which is a consideration if that material is anything but steel.

Column Restraint

Steel is very strong in compression, and consequently, steel columns may be designed to be taller in relation to their cross-sectional area without the risk of crushing.

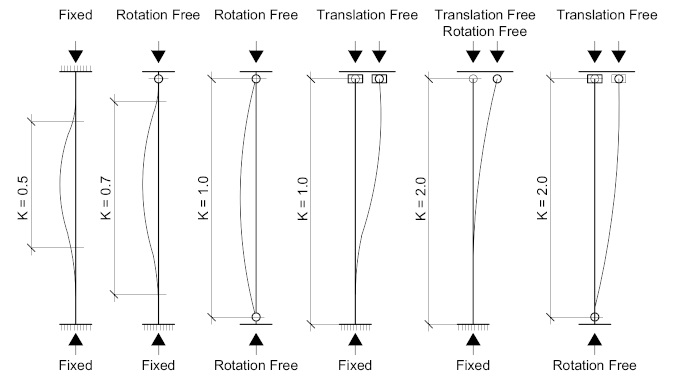

A steel column is most likely to fail as a result of ‘Buckling’, and its propensity to buckle under load is influenced by the way its restrained at the top and bottom. Such restraints may be categorized as: Fixed, Pinned, or Free.

A Fixed-End does not allow rotation or Translation (Horizontal Displacement) in any manner

A Pinned-End allows for some rotation in one direction but is secured in such a manner that will not allow translation.

A Free-End will allow for both rotation and translation. Such a condition can only apply to one end of the column, while the other end must be fixed to ensure stability

Buckling is measured from the ‘Effective-Length’ of the column corresponding to the section of the column which deforms as a single curve in the shape of a pin-ended buckle. The type of end connection will determine how much restraint is offered to the column. The Pin-Ended column will be able to buckle more freely than a Fixed-Ended column. The above diagram illustrates the varying degrees of buckling according to the manner in which the column is restrained.

Note! That K = the column effective length factors in relation to the column total length.

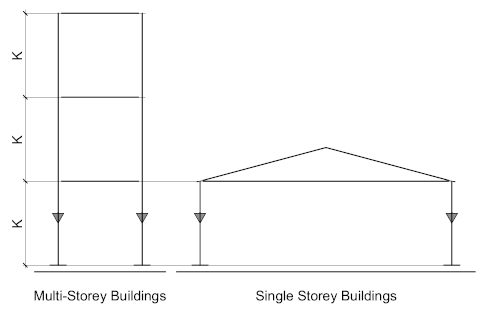

Columns in Single and Multi-Storey Buildings

Multi-storey columns are generally restrained at each floor level, so the effective-length (K) is essentially based on the distance between floors.

Thus, the column length between floors and the method of restraint in both the x-x and y-y axes at each floor level becomes significant when determining the effective-length.

In a multi-story structure, the columns can have different degrees of restraint between different floors. The bottom length of the column, between the base and the first floor is effectively held in position at both the base and first floor, while being restrained at the base. The upper floors will be effectively held in position, but not restrained, therefore the effective lengths will differ.

Single-Story columns tend to require a bit more thought, because the effective-length is determined by the manner in which the overall structure is restrained. Generally, such buildings are fixed at the base, while the top is effectively un-restrained. The amount of permitted rotation and translation is dependent on how the roof is connected to the columns, whether it be a ‘Rigid’, moment resisting connection, or whether it’s Pin-Ended.

A ‘Rigid’ connection will offer some resistance to rotation and translation, while a Pin-ended connection may require some other form of restraint.

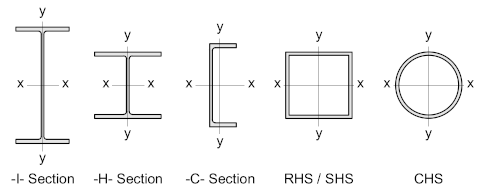

Column Profiles

Just about any steel profile, or shape, can be used as a column, but there are two factors that go toward determining which profile should prove adequate:

- The Slenderness Ratio, and

- The Axis

The Slenderness Ratio is the ratio between the column’s effective length to the least radius-of-gyration of its cross-sectional area. As a rule-of-thumb, a ‘Short-Length’ column is one whose slenderness ratio does not exceed 50

An ‘Intermediate-Length’ column has a slenderness ratio of between 50 and 200, while a ‘Long’ column has a slenderness ratio greater than 200.

All Hot Rolled Steel Sections have a strong and weak Axis designated X-X and Y-Y and columns will tend to buckle in the direction of the weaker Axis. The strong axis is usually in the deeper of the two which means that the -I- and -C- sections are more resistant to buckling in one direction than the other, making them ideal for use as horizontal beams, where the main strength of the section is required in the direction of bending. If they are to be used as columns, their strength will be determined by their ability to resist buckling in their weaker direction.

The -H- section however, is manufactured primarily for use as columns, these sections have a similar resistance to buckling in both the X-X and Y-Y axes of the cross-sections, and having thicker webs and flanges makes them more resistant to axial compression forces.

SHS (Square Hollow Section) and CHS (Circular Hollow Sections) are symmetrical and the X and Y axes are identical.

Fabricated tapered sections may also be used as columns, by designing the column to be thickest at its maximum point of deflection and tapering it off toward the ends, this can make it structurally very efficient, but the cost is often prohibitive and is usually only practically considered if the overall aesthetics demand such a solution.