Introduction

A Truss or Lattice-Girder is essentially a triangulated system of interconnected elements which connect at common work-points or ‘Nodes’, they are designed to primarily resist bending with the top chord being the compression element, and the bottom chord being the tension element. The diagonal lacing being axially loaded will work either in tension or compression depending on how the elements are configured.

A Truss or Lattice-Girder is essentially a triangulated system of interconnected elements which connect at common work-points or ‘Nodes’, they are designed to primarily resist bending with the top chord being the compression element, and the bottom chord being the tension element. The diagonal lacing being axially loaded will work either in tension or compression depending on how the elements are configured.

They may be formed from almost any combination of steel profiles, but generally they are fabricated from angles. channels, or Square, rectangular or circular hollow sections. They may be either bolted or welded or a combination of both.

They are used primarily for long-span, light-weight applications, but due to their relatively high fabrication costs, their use as conventional beams have been largely supplanted by plate-girders, which though much heavier, their ease of fabrication makes them generally more cost efficient. As a consequence, the use of latticed-girders is now largely limited to wide roof spans, bridges, elevated gantries, and wind-girders.

Truss Configurations

It will be found that trusses are configured into fairly well defined types, which include:

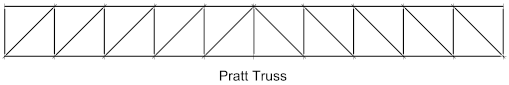

Pratt Truss

Which is used for roofs where vertical gravity loads are predominant. The top and bottom chords are in compression and tension respectively, while the vertical and diagonal members are in tension or compression.

The Pratt-Truss is sometimes referred to as a Bridge-Truss, where two trusses are ‘boxed’ and stabilized laterally by means of horizontal bracing across the top and bottom, forming a ‘laced-tube’ with the bottom chord forming a deck.

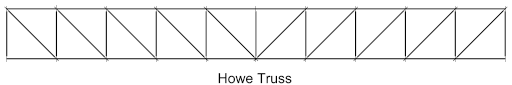

Howe-Truss

Which is essentially an inverted Pratt-truss and is primarily used for roof trusses where ‘uplift’ loads predominate. They are found in wide-span open structures.

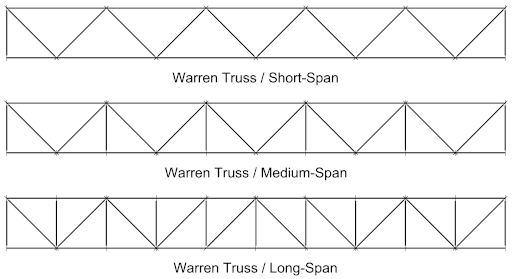

Warren-Truss

This is flexible in that the diagonal members work alternately in tension and compression. Additional vertical compression members may be added, enabling it’s use for longer spans. This truss type is also used as the horizontal girder for crane gantry-girders to resist the horizontal forces applied by the crane-trolley.

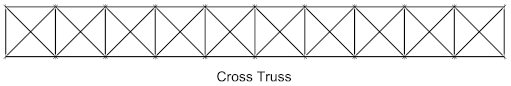

Cross Truss

This is a superposition of two Warren-Trusses and is commonly used for long-span horizontal wind-girders, especially where the diagonal members are excessively long.

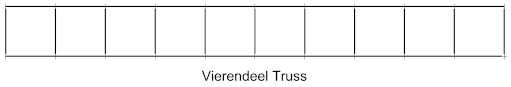

Vierendeel Truss

The one exception to the conventional triangular configuration is the Vierendeel truss, which is made up of rectangular rather than triangular frames. Because of the lack of diagonal members, they employ Moment Connections to resist substantial bending forces. This truss configuration has been used for bridges – but more commonly, they are used in structures where large Shear Walls or diagonal elements would interfere with the building’s aesthetics or functionality

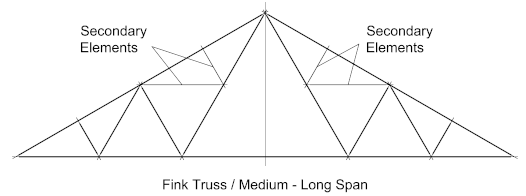

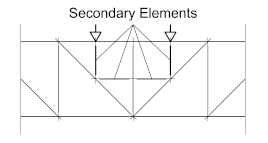

Secondary Elements

Secondary members (as with the Warren-Truss) may be added to create intermediate loading points, and to limit the buckling length on members in compression.

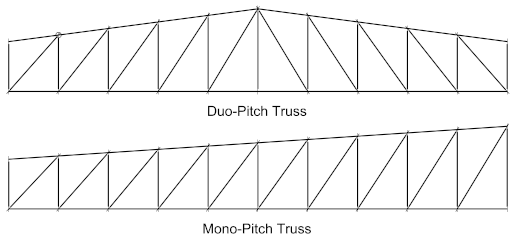

Mono / Dual Pitched Trusses

For any of the above truss configurations, the top chord may be ‘sloped’ to form either a single or duo-pitch truss (As illustrated).

Pitched Truss

The most common Pitched-Truss configuration is the Fink-Truss which is commonly found on older high-pitch roofs.

High-Pitch roofs seem to have fallen out of favor for modern industrial structures due to their seemingly complex construction and relative difficulty to erect, but they are still used widely for residential homes and other such light commercial and residential structures.