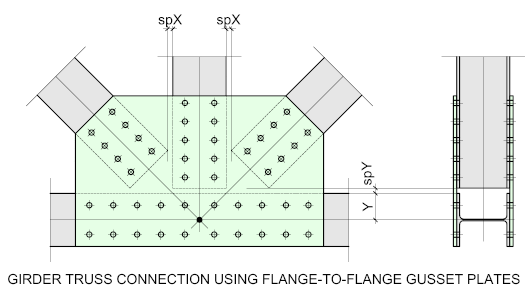

This type of connection is commonly found in Girder Trusses, particularly Bridge Girders. The horizontal beam(s) may be orientated with the flanges top and bottom or rotated through 90° with the flanges to the side. The advantage with the latter is that the beams and bracing members can be of the same section making it easier to fabricate and assemble on site. This orientation will create a trap for water and debris, in which case drain holes may need to be provided.

This type of connection is commonly found in Girder Trusses, particularly Bridge Girders. The horizontal beam(s) may be orientated with the flanges top and bottom or rotated through 90° with the flanges to the side. The advantage with the latter is that the beams and bracing members can be of the same section making it easier to fabricate and assemble on site. This orientation will create a trap for water and debris, in which case drain holes may need to be provided.

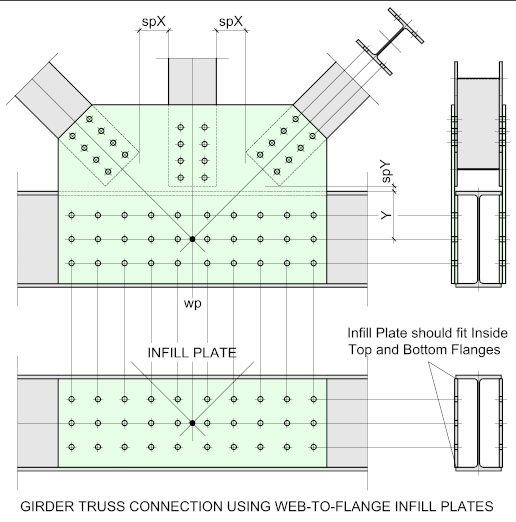

If the Girder beams are to be mounted with the flanges top and bottom, infill plates will need to be provided between the flanges of the beam to compensate for the differing member widths. These plates should be shop-welded to the girder beams with at least half of the plate fitted between the flanges – this will relieve the stress on the weld. Details such as this must be confirmed by the responsible engineer.

As with all other option in this series, bracing members are set out to a common Work Point located at the intersection of the centre lines of the beams, columns and bracing members. Other options for locating the Work Points can be found at Vertical Bracing - Setting Out

The Strike-Planes are represented by spX (Vertical) and spY (Horizontal). The relative sizes of the column and beam together with the angle of the brace will determine which of the two will be the lesser. The lesser value should ideally be between 10 and 20 mm. This will ensure the joint is compact while allowing for normal fabrication and erection tolerances.

For more information on Strike-Planes refer to Vertical Bracing - Setting Out