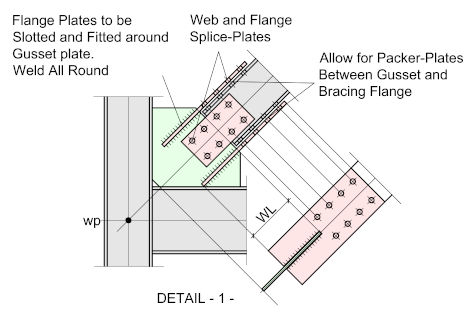

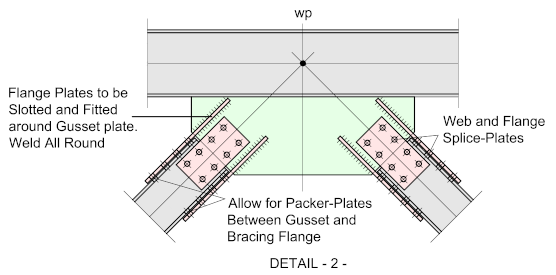

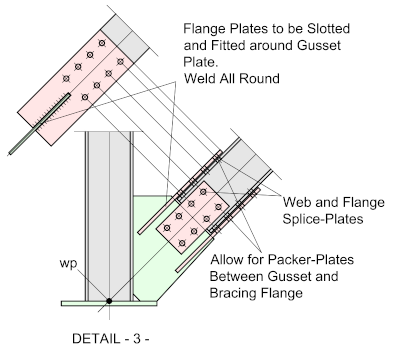

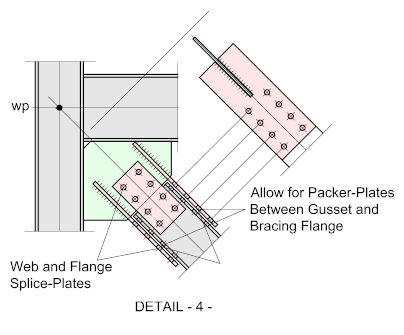

The following typical connections apply to –I- or –H- profile bracing which may be subject to tension or compression. The flange plates are slotted to ‘wrap around’ the gusset plate and shop welded in position. The bracing members are then site-bolted to the flange and web plates. Any misalignment may be compensated for by allowing for packer-plates between the bracing member flange and the flange plate to aid erection.

The following typical connections apply to –I- or –H- profile bracing which may be subject to tension or compression. The flange plates are slotted to ‘wrap around’ the gusset plate and shop welded in position. The bracing members are then site-bolted to the flange and web plates. Any misalignment may be compensated for by allowing for packer-plates between the bracing member flange and the flange plate to aid erection.

These connections are fairly complex and require great care during the fabrication process, as little as 0.5° deviation can create misalignment problems resulting in headaches for the erectors. It’s not unusual for the bracing set to be trial assembled in the workshop prior to delivery to site.

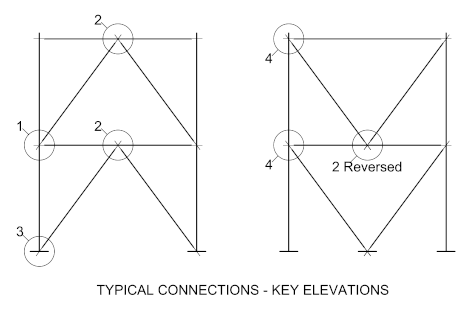

The bracing members are set out to a common Work Point located at the intersection of the centre lines of the beams, columns and bracing members. Other options for locating the Work Points can be found at Vertical Bracing - Setting Out

If the bracing is to work in compression, Slip-Resistant bolts will most likely be required.

The usual rules that apply to the strike-planes will be found not to apply here as the values for spX and spY (See Vertical Bracing - Setting Out) will be determined by the inclusion of the flange plates. In some circumstances the length of the gusset-plate may become excessive and could create a bending moment in the plate, especially if it’s likely to work in compression. This will need to be addressed by the responsible engineer.

In each case the gusset-plates are indicated connecting to the column flange - For further information on connecting to the column web go to Vertical Bracing - Setting-Out