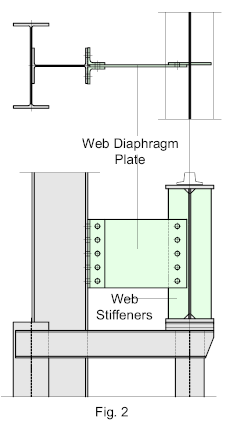

Column Base Plates

0The Column Base-Plate is welded tp the base of the column and in turn, fastened to the foundation by means of specially designed Anchor Bolts. They have to deal with a variety of load conditions including, Compression, Shear and Rotational Moments. All column bases will have to deal with a combination of these loads to a greater or […]

Column Base Plates Read Article »